Circulating Fluidised Bed Coal Gasification Technology for High Ash Indian Coal – Fuel & Dri Syn Gas

National Coal Gasification Mission

“We have set a target to gasify around 100 million ton of domestic coal by the year 2030. Coal Gas will be used in transport & cooking while urea and steel from gasification will promote manufacturing. Latest technology can be introduced to make gas from coal and environment will be protected with coal gasification” – SHRI NARENDRA MODI, Hon. Prime Minister of India.

What is Gasification?

Gasification is a robust, proven, and versatile technology that produces syn gas (carbon monoxide (CO) + Hydrogen (H2)) from reaction between carbon, oxygen and steam air at low to high pressure (atmospheric to 30 bar g) and temperature ranging from 1000oC to 1600oC.

Gasification not only captures heat but also Chemical value of feedstock like Coal.

However, Indian coal has challenges of high ash (>35%) thermal non-coking coal and high moisture (48% – 54%) lignite which calls for need most applicable technology.

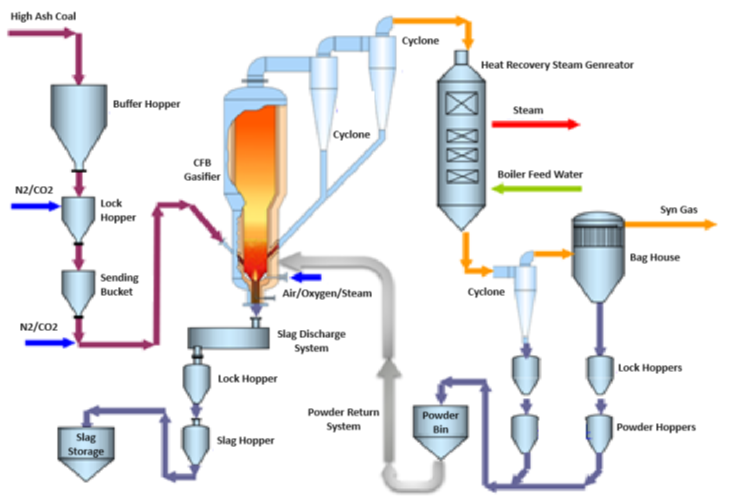

Ash is removed by gravity from the gasifier and is discharged into a system for depressurization and disposal. The gasifier maintains a low level of carbon in the bottom ash discharge stream and achieves overall carbon conversions that can exceed 99%. Cold gas efficiencies of over 80% and carbon conversion of up to 99% have been repeatedly demonstrated on a commercial scale in CFB operating plants.

CFB is more fuel-flexible, utilizing low-rank and other high-ash coals, and offers higher efficiency than competing gasification technologies, due to the fluidized bed design and resulting long residence times of the reacting particles.

Fines carried over from the fluidized bed are separated from the syngas prior to heat recovery and syngas cleanup. The product syngas is essentially free of tars and oils due to the temperature and residence time of the gases in the fluidized bed, simplifying downstream heat recovery and gas cleaning operations.

CFB gasification adopts three-stage waste heat recovery process, which can recover the heat of high temperature syngas to produce high temperature and high pressure steam along with air/oxygen preheating resulting in overall high thermal efficiency.

Technology Overview

Our Partners

JINAN HUANGTAI GAS FURANCE CO. LTD.

Normal Pressure – Air Fed – Fuel

- In Operation Since 2009

- > 22 Operational plants

- Higher calorific value fuel : 1250 kcal/Nm3

- Continuous 21 month gasifier campaign

Ease of Operation & Maintenance

Shanghai Zepu Engineering Technology Co. Ltd.

HIGH PRESSURE – OXYGEN FED – DRI SYN GAS

- Patented and improvised CFB technology

- High Pressure – 3 bar to 40 bar

- Proven commercial scale plants from basic engineering, detailed engineering, and EPC solutions for clean syn gas

- Customised solution for various end-use applications such as clean DRI Syn Gas, Methanol, DME, Ammonia, Urea and SNG

- Strong R&D in line to handle low-rank coals of high ash and moisture

Technical & Economic Advantages

Government of India Incentives

CFB is the only proven commercial-scale technology for high ash Indian coal gasification projects to benefit from all Government of India incentive schemes:

- Viability Gap Funding (₹ 8500 cr)

- Dedicated Coal linkages assurance

- Notified Coal Pricing (Lower coal price than auction rates)

- 50% rebate on captive mine dedicated to surface coal gasification

- Coal Price GST waive off (~ 400 Rs/ton)

National Steel Mission – Guarantee off-take for steel makers

As India’s major contributing GDP National mission to grow to 300 million ton per annum steel production by 2030 from 127 million ton per annum as of 2024 to support strong infrastructure growth, steel producers will also be served by the proven commercial-scale CFB technology clean DRI syn gas from high ash Indian coal gasification projects. These projects will also be 100% Green Hydrogen compatible for coming decades as against Blast Furnace route which depends on high price of coking coal imports.

CFB Coal Gasification – “IN India FOR India”

Technology Selection – Why CFB?

Commercial scale three technologies which are Fixed Bed, Entrained Flow and Fluidised Bed technologies below pros and cons:

Based on various interactions organised by the Ministry of Coal for the implementation of the National Coal Gasification mission it is evident that all major technology developers such as Thermax, BHEL and CSIR-CIMFR have chosen CFB starting with pilot scale as the most suitable technology for Indian high ash coal.

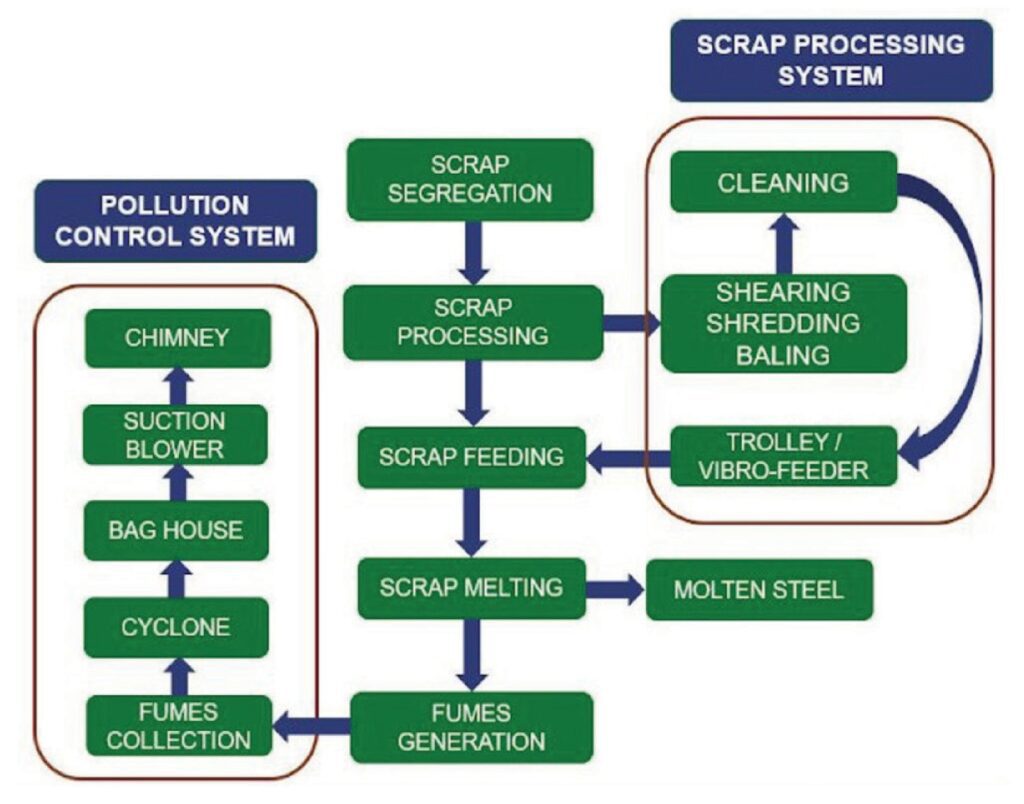

CFB Technology – How it Works?

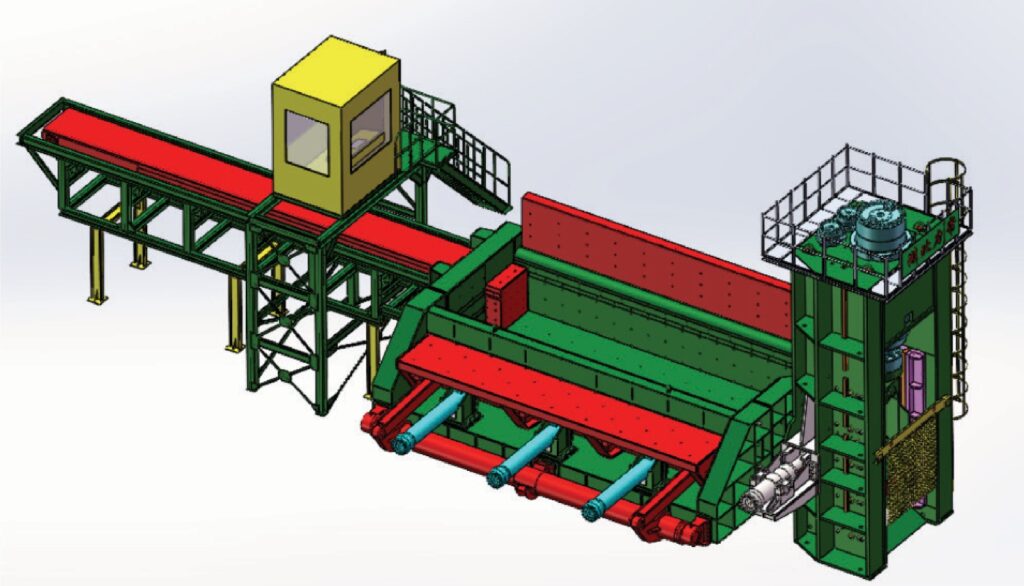

Grinding, sorting, shredding, and/or drying may be required to bring the feedstock up to the gasifier feed system’s standards of <10 mm particulate size.

The prepared feedstock is pneumatically supplied to the CFB gasifier vessel, which is a bubbling in circulating fluidized bed reactor. The feedstock combines with air/oxygen and steam as gasification in the fluidized bed, uniform temperature of 1000 oC is maintained to provide high carbon conversion and non-slagging conditions for the feedstock’s ash. The CFB gasification process is carried out as partial oxidations as gasification of feedstock with agglomeration and separation of ash.

Technology Features & Advantages

Adaptability of CFB Syn Gas

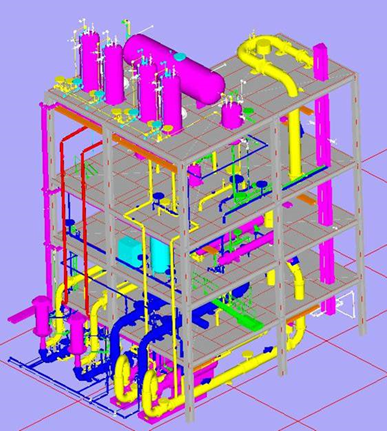

The syngas is subsequently processed for use in a variety of applications, including direct reduced iron (DRI) steel production, methanol, fertilizers like ammonia, Urea, further ammonium nitrate, substitute natural gas (SNG) and di-methyl ether. Pre-combustion carbon capture CFB Gasification in syngas cleaning systems downstream of the gasification process makes it useful for CO2 removal as raw material for downstream products and potential to make it carbon neutral technology solution.

Compatibility with downstream DRI Licensors

CFB technology has full flexibility of H2/CO ratio, CO2 removal adjustment as required by all global DRI technology providers offering wide adaptability for the complete technical and commercial optimisation for steel makers.

Flexibility of CFB offering

CFB gasification adopts oxygen-enriched gasification, and the N2 content in syngas can be effectively controlled below 5% or lower. CFB gasification pressure is high avoiding any downstream compression requirement, and the CH4 content in the syngas can be up to Controlled ideal for DRI steel-making feedstock.

Compatibility with downstream DRI Licensors

CFB technology has fully aligned requirement of H2/CO ratio, and CO2 removal adjustment as required by all global DRI technology providers offering wide adaptability for the complete technical and commercial optimisation for steel makers.

Optimized process configuration

Commercial DRI Plant – Ready for offering

0.5 MTPA DRI – Vertical Shaft Kiln

Clean DRI Syn Gas Process

CFB offers the flexibility of a partial water shift gas process unit for the downstream vertical shaft kiln. Also, this technology is capable for using wide range of O2 purity from Air Separation unit and CO2 removal unit required levels.

Conclusion

DEV ENERGY with its successful Turnkey project design and implementation proven solution provider has delivered > 23 years and is committed to taking National Gasification mission on a fast implementation model with low capital cost using a Circulating Fluidised Bed Technology with commercial scale projects. We are also well aligned with the “Make in India” model even with China Partners as maximizing local manufacturing and minimum proprietary scope (<5%) with no technology transfer fee requirement due to Dev Energy exclusive partnerships already in place. With experienced & qualified EPC solution provider not only can coal gasification projects on fast track but also provide after sales service and operational success for sustainability of high ash Indian coal gasification with CFB.

References

- https://pib.gov.in/PressReleasePage.aspx?PRID=1999220

- https://coal.gov.in/sites/default/files/ncgm/ncgm21-09-21.pdf

- https://www.netl.doe.gov/carbon-management/gasification#:~:text=Gasification%20enables%20remediation%20of%20wastes,net%2Dzero%20energy%20system%20basis.

- https://pib.gov.in/PressReleasePage.aspx?PRID=1944388