Why is Scrap Processing Important?

Deteriorating scrap quality has necessitated the preparation of scrap through scrap processing machines for better efficiencies in melting furnaces. Processed scrap is denser and cleaner for faster charging in the furnace.

Processed scrap also consumes less power per ton of steel produced, resulting in high productivity for the furnace. Dev Energy scrap solutions can be tutored to plant needs and help processors manage any type of input scrap; while increasing scrap value and employee safety through efficient of scrap handling. We proudly provide robust industrial shredders and shears in the market today. Our systems not only make scrap easier to manage, then low-cost operations reduce waste thus lowering the total cost and providing immense value to the company.

Application Impacts

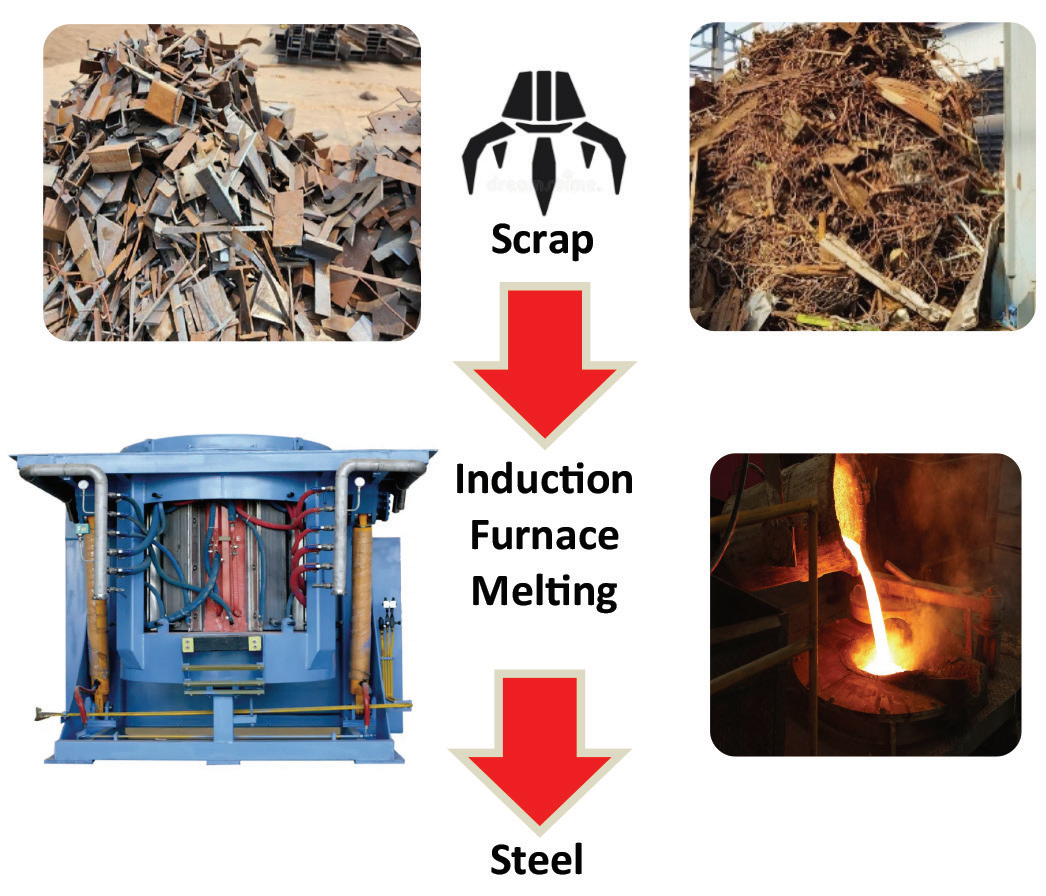

Steel making is a very competitive business. The secondary steel manufacturers have to be efficient and their cost has to match the primary producers who make steel from Iron ore. The secondary steel making process has to use the Electric Arc or Induction Furnaces to make molten steel. In India about 45% of the steel is produced using Induction Furnace with the use of two basic raw materials Sponge Iron and Scrap Steel.

Dev Energy - Benefits

- Power Consumption LOWER BY ~ 15 %

- Heat Time REDUCTION BY ~ 20 %

- Increase in Production Per Heat Unit

- Increased Life of Furnace Lining

- Reduction in Slag Formation

- Reduction in Scrap Purchase Cost

- Less Fumes & Cleaner Environment

Main Process – Scrap + Induction Furnance

End to End Solutions

These factors can be achieved with streamlining the total process to the desired results. To start with, the purchase of the right kind of raw material suitable for the furnace and the end product need to be identified.

SMS using Scrap as the main raw material face a major challenge as the scrap is never consistent and it is impossible to define parameters for processing it. The complete process from scrap purchase to melting need to be aligned to the desired results.

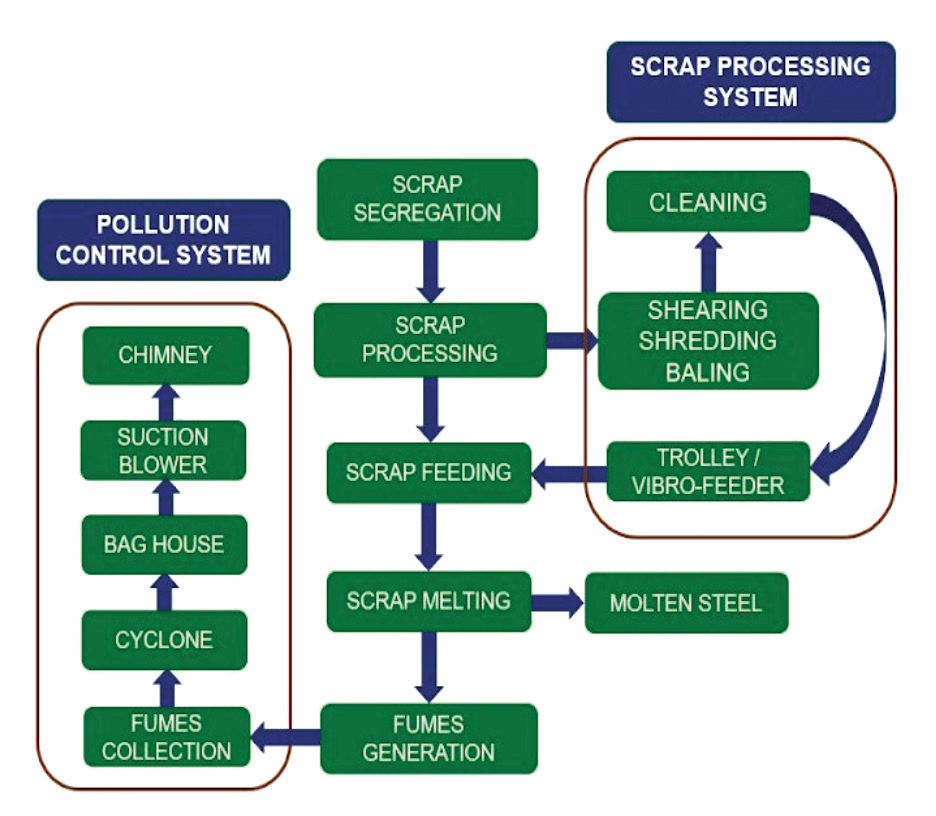

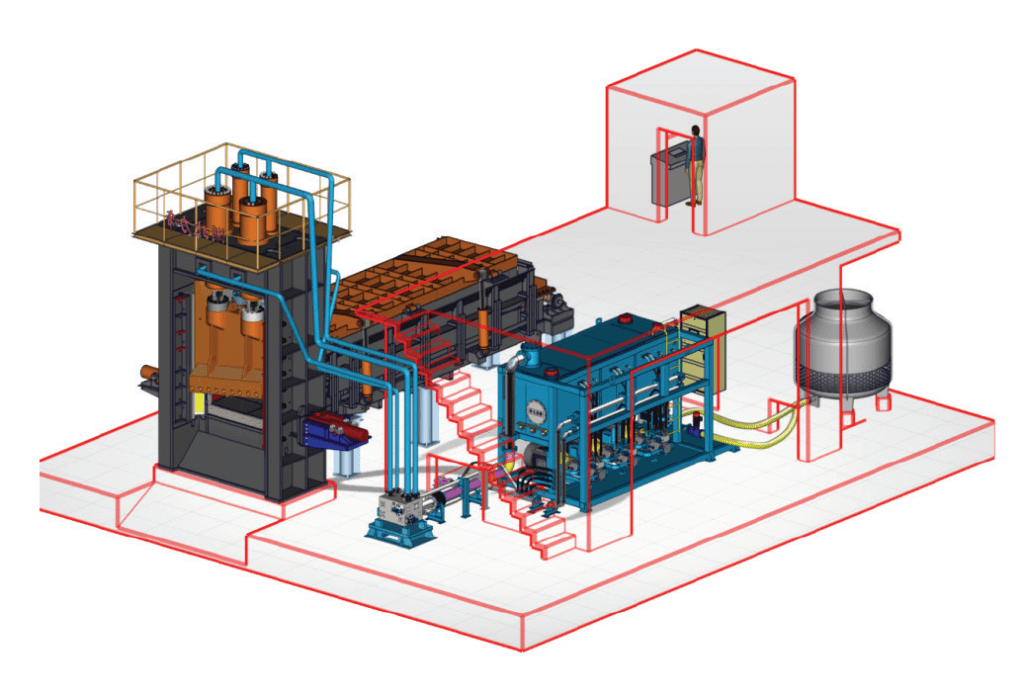

Dev Energy has developed expertise to provide innovative turnkey solution for efficient scrap segregation, processing and feeding in the furnace. This feeding system also has to be integrated with the pollution or Flue control system generated during melting.

Power is the major cost in making steel. Dev Energy has been actively working on reduction of power with its dynamics and interrelation to scrap processing. The scrap shape, density and size are the variables that determine the time required for melting. The input scrap that is improper results in longer time for melting and higher power consumption.

Offerings

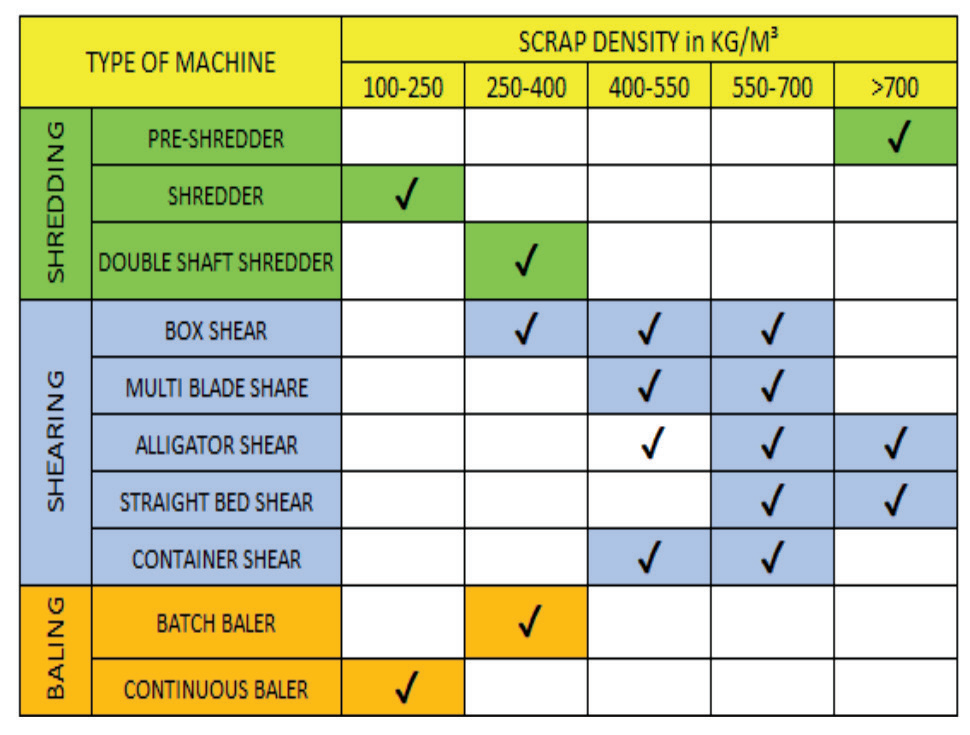

The solution is to process the scrap in the proper parameters using machinery matching the type of scrap.

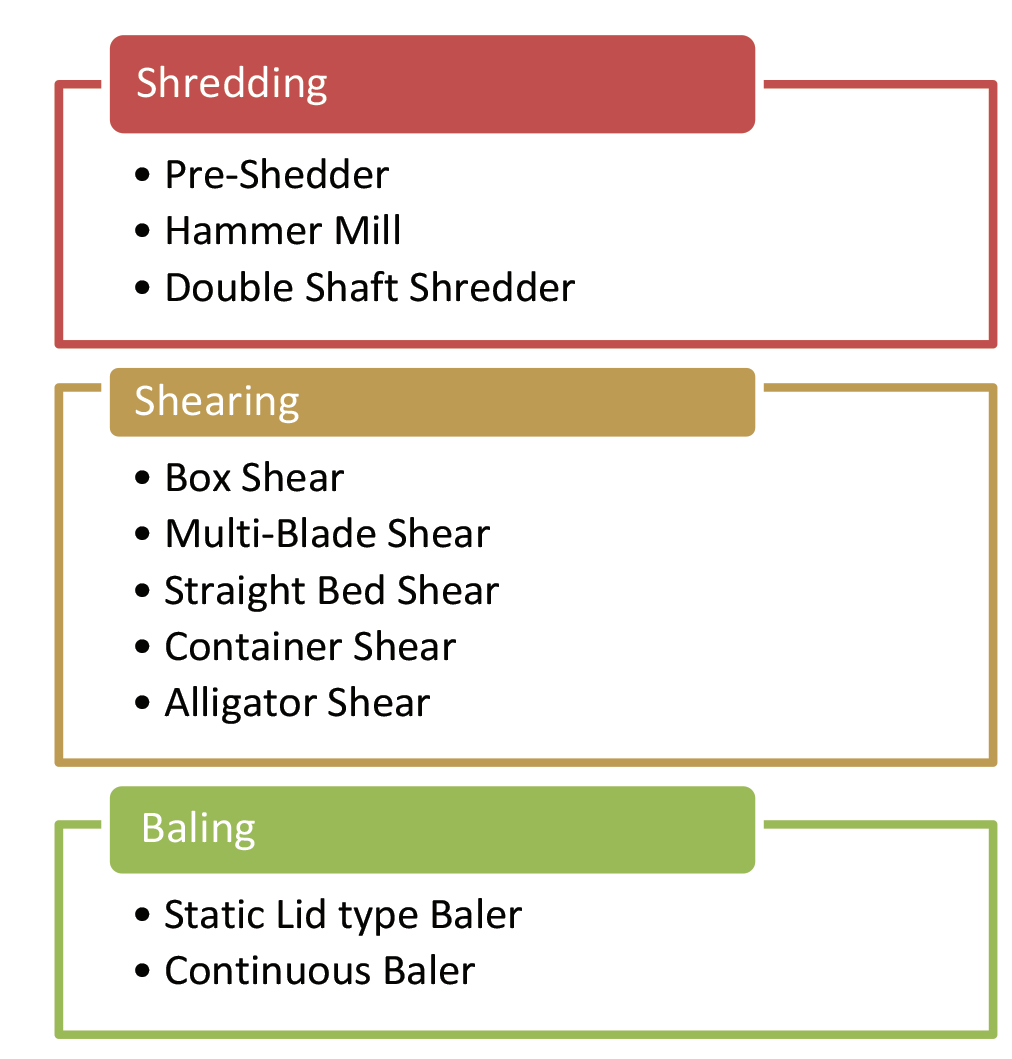

The scrap can be processed using three broad methods namely Shearing, Baling and Shredding. The process identification depends on the type of Raw Steel Scrap, its density, its size, its cleanliness level, the size of the furnace, power density of the furnace etc. There are various types and size of machines available to process scrap from 01 to 100 t/hr.

These scrap processing machines must accompany with matching scrap unloading and segregation system. Once the scrap is processed the system design should be able to feed the same to the furnace. Dev Energy provides the complete range of turnkey solutions for unloading and segregation, processing scrap and the material handling systems for feeding scrap.

The perfect implementation results in reducing the power consumption up to 8% and heat time up to 10% resulting in net cost saving of 10%.

Processed Scrap Targets

Final Density > 1000 Kg / m3,

Size < 600 mm,

Dust ~ Negligible

Machine Selection

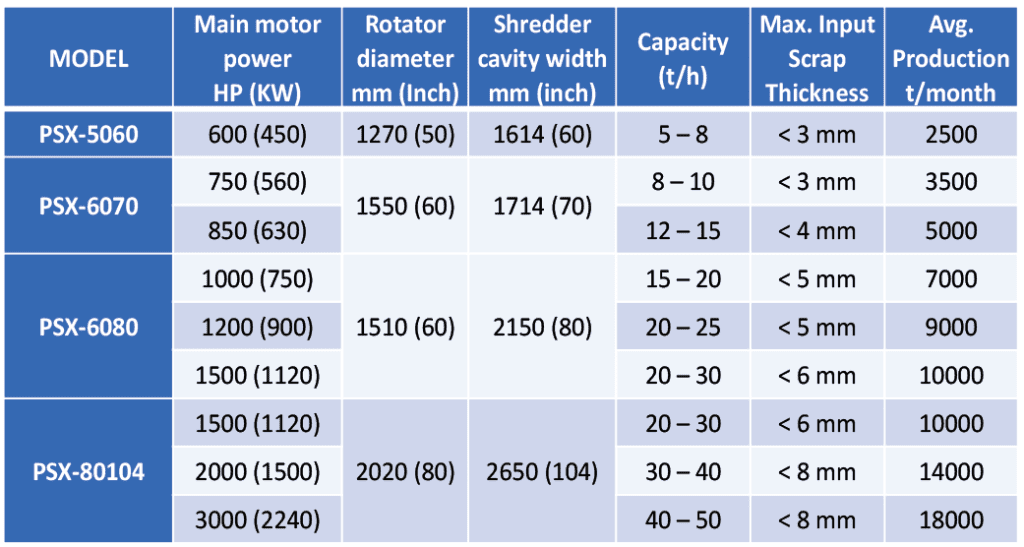

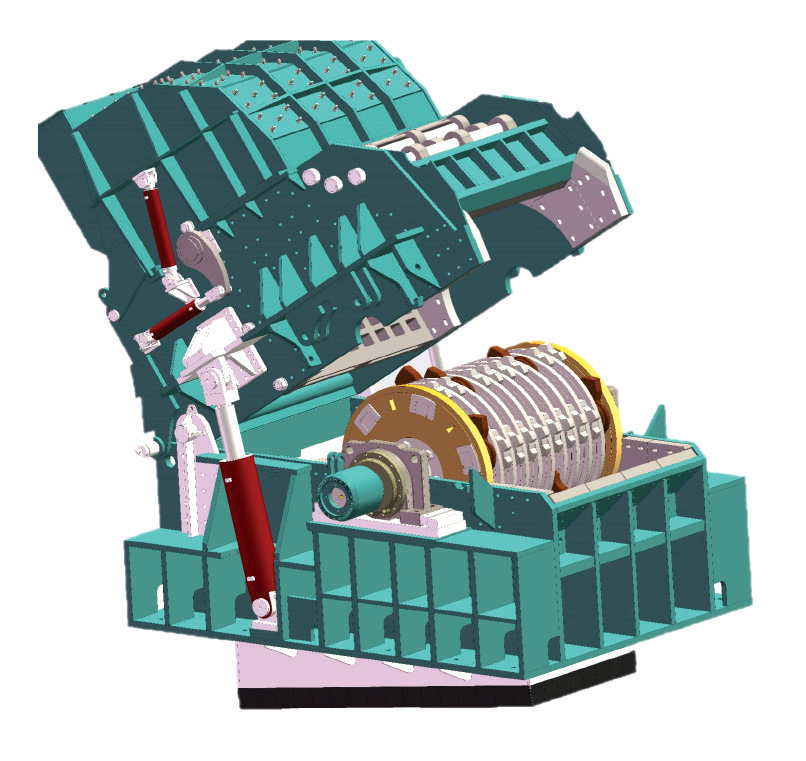

Shredder

Output density to 2 ton/m², ≥ 99% metal recovery in process, Non-Ferrous segregation, Bag House De-Dusting system, Z Box Air-cleaning system.

Lowest operation cost ~ INR 650 / t

Flexible Soution Offering

Sound Proof Enclosure, 2nd Magnetic Separator, Blue Smoke Inhibitors, Video monitoring system, Man Shorting conveyor.

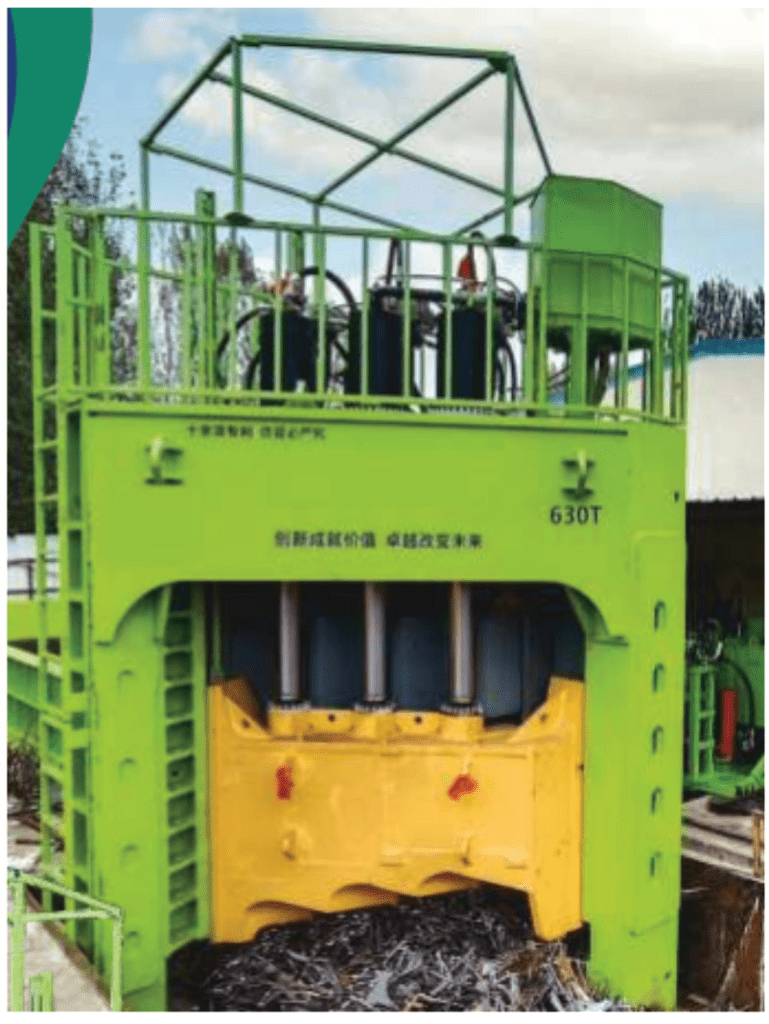

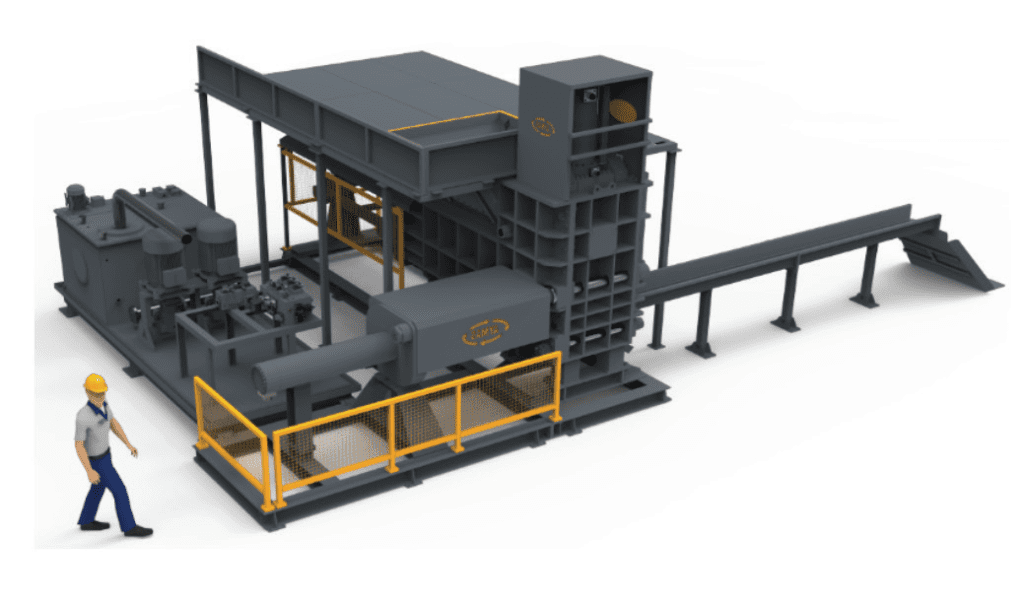

Box Shear

Ideal for all variety of Scraps, Three sides of compression, Additional side press & clamping, Output Scrap Density ~ 1000 Kg/m³

Operational Expenses ~ INR 250 / t

Multi-Blade Shear

LID compression and top clamp compression, Size of shearing < 500 x 500 mm (5 Pieces), Output scrap density ~1000 kg/m³, Ideal for medium & heavy scrap

Low operation cost ~INR 90 / t

Straight Bed Shear

Output Scrap Density ~ 900 Kg/m³, Automatic Blade Tightening, Side Compression & top clamp compression, Option of Lid cover / Feeding bucket

Low operational cost ~ INR 100 / t

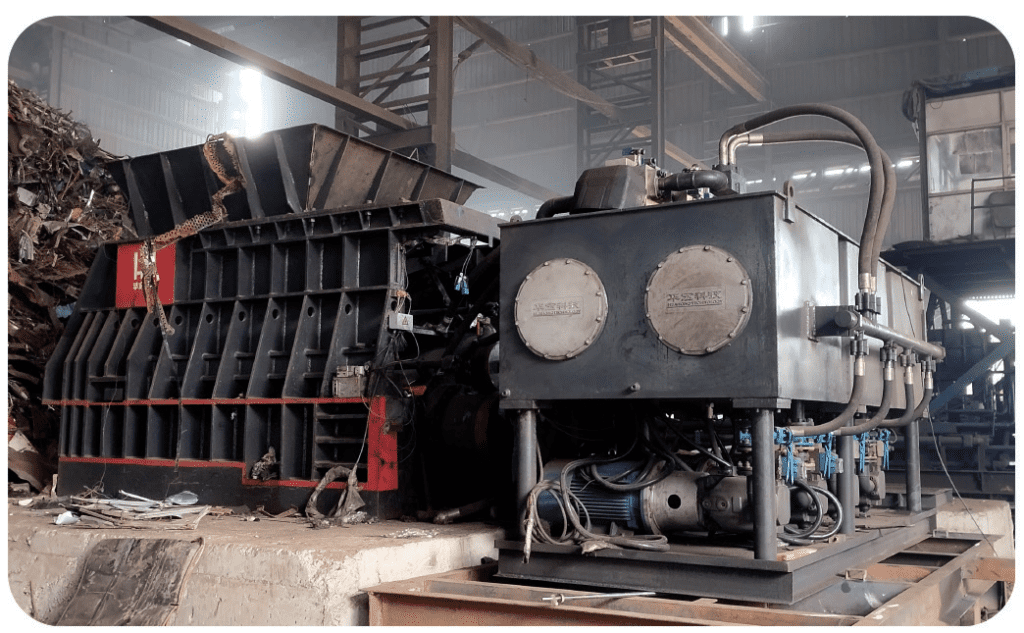

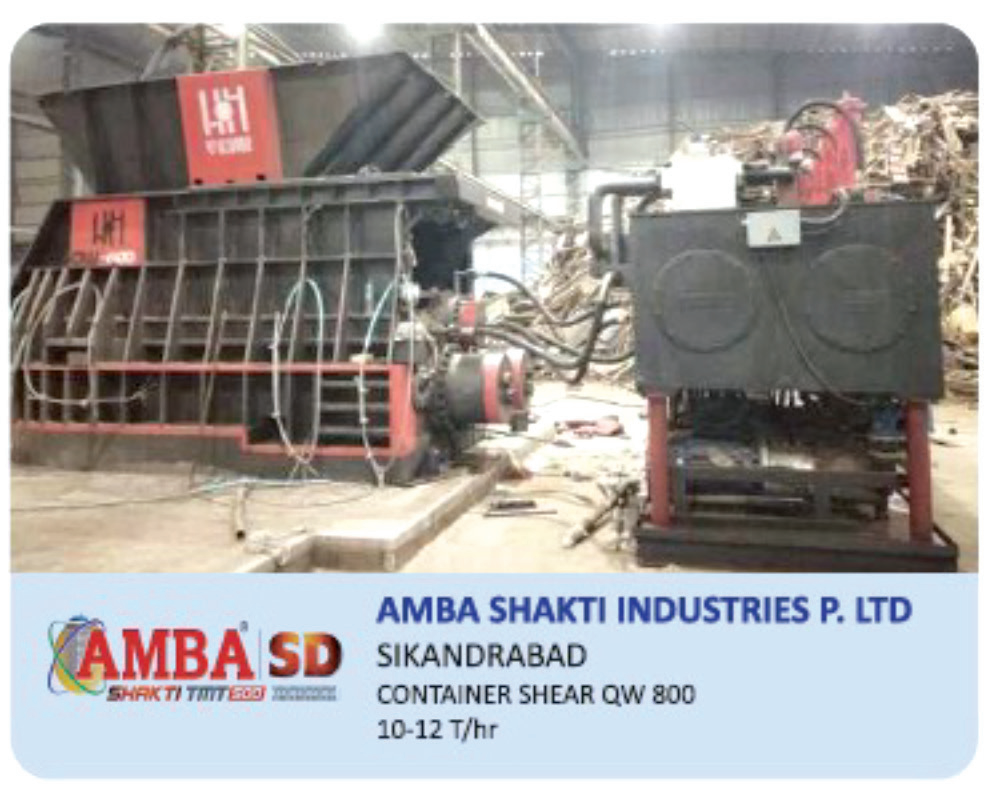

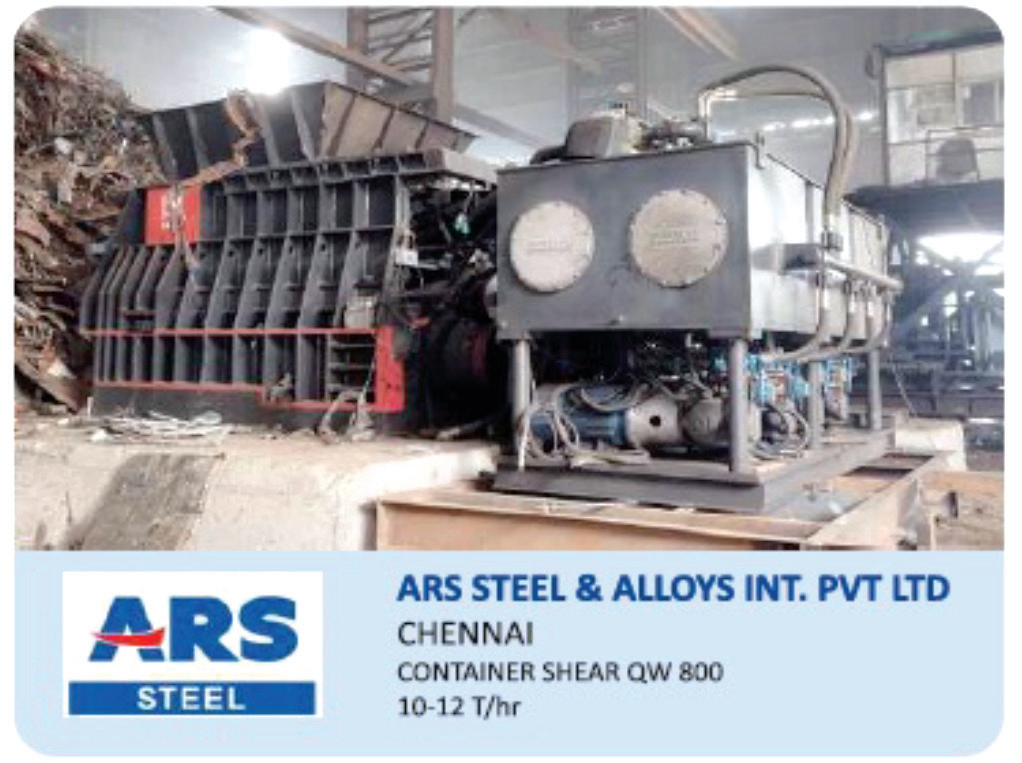

Container Shear

Ideal for Medium & light Scrap, Simple operation of horizontal shearing, Output Scrap Density ~ 700 Kg/m³

Low operational cost ~ INR 100 / t

Alligator Shear

Ideal for Long and Heavy Scrap, Manual Operation

Low operation expense ~ INR 50 / t

Continuous Baler

Continuous operation, Three sides compression, Bales density up to 3 ton / m³, Output Speed ~ 100 bales / hr

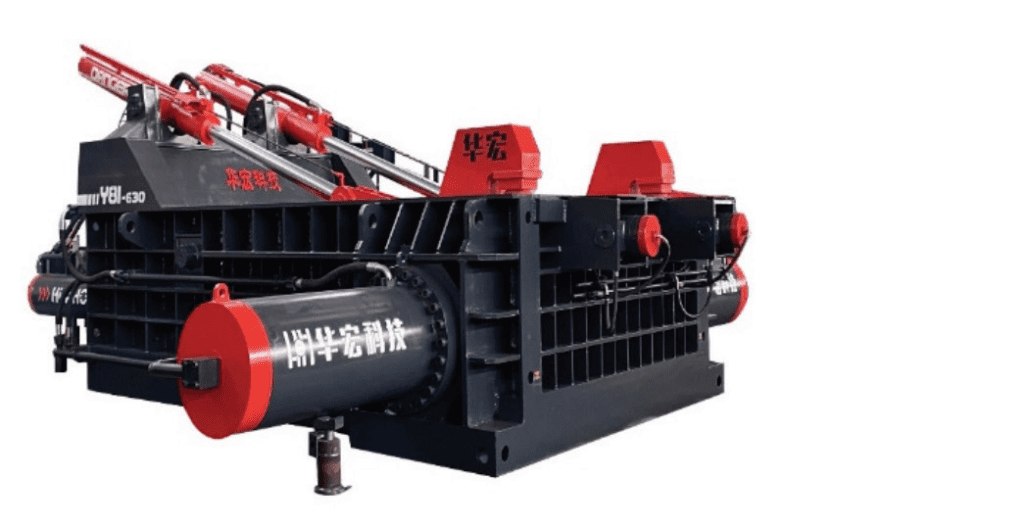

Large Baler

Three sides compression baler, Automatic PLC Driven Operation, Cycle time ~ 120 sec, Fully hydraulic driven operation, Option for Centre / Side FLIP out

Low operation expanses ≤ INR 75 / t

Crane

360 Rotation arm, 30 sec cycle time, grad capacity ~ 0.9 m3, stationary and mobile machine with Diesel or electric option.

Dev Energy provides all these combined solutions which delivers value for money to end user in one package.

Dev Energy – Projects

Three sides compression baler, Automatic PLC Driven Operation, Cycle time ~ 120 sec, Fully hydraulic driven operation, Option for Centre / Side FLIP out

Scrap Procssing Unit – Green Steel

Based on bench marks of various primary and secondary steel making process with optimized solution using effective scrap processing as mentioned here not only delivers techno- commercially effective solution but also makes move towards Green Steel lower emissions in rage of 0.6 to 0.8 CO2 t / t of Liq. Steel.

As closer to targeted by global standard for Green Steel definition value of 0.4 CO t / t of Liq. Steel.

Conclusion

Dev Energy with its successful EPC/Turnkey project design and implementation is a proven solution provider. Dev Energy has delivered successful projects for > 23 years and is committed to Sustainable Scrap Processing Solutions. With exclusive global partnerships already in place, DEV ENERGY can deliver 3R’s REDUCE, REUSE and RECYCLE.