Introduction

Steelmaking has been one of the most polluting industries since ages. Today, steel melting shops are under increasing pressure to meet stringent environmental norms set by the National Green Tribunal and State Pollution Control Boards. There has been no design innovation in the management of air pollution for the induction furnaces which are the mainstay of the steel making in secondary steel sector in India. The conventional solution with side hoods and scrubbers often captures only about 60% of emissions, falling short of compliance and incurring high operating costs due to heavy energy consumption.

Dev Energy, in collaboration with our Chinese technology partners, has developed through iterative innovation an advanced Fume Extraction Systems. The advantages of the system is that it captures > 95 % fumes in primary hood and eliminates the need for secondary system. The dust collected is dry containing Zinc proving the user great source of revenue. The integration to the scrap-handling and molten transfer solutions makes steel production cleaner, safer, and more commercially viable.

Let us examine the key features of the solution step by step

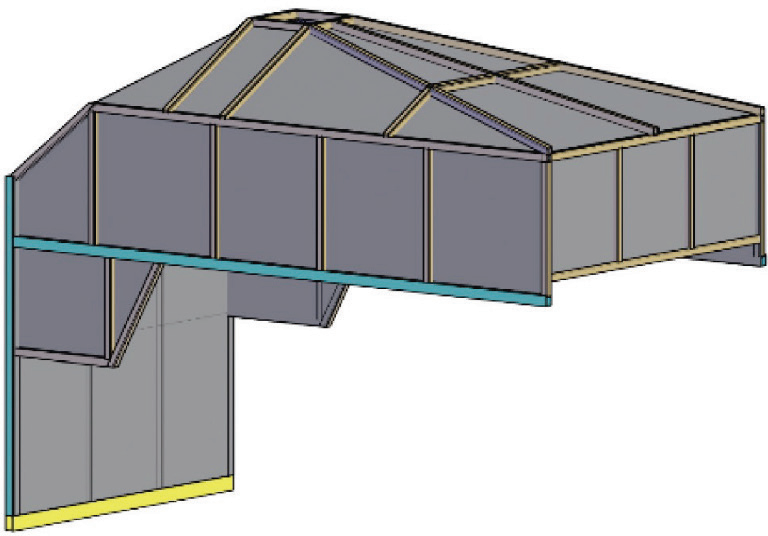

Dog House – Complete Fume Capture

One of Dev Energy’s flagship innovations is the Dog House, a specially designed hood that completely covers the induction

furnace and the feeding system. The suction of the fumes is from the top of the hood enabling easier flow dynamics of the fumes.

The Dog House has the following features

• Fume suction Capacity >95%

• One Single hood for both crucibles• Design compatible with Scrap feeding trolleys

• Design compatible with Scrap Pusher

The maximum fumes are generated with the molten metal is poured from induction furnace to the transfer ladle. The Dog House design is compatible with pouring of Molten Metal into the Ladle Car within the Dog house capturing all the generated fumes.

The Dog House is movable on its own gantries and thus need no overhead cranes. The Dog House is lined and painted with specially developed Heat-resistant paint which has resistance up to 1200 C.

Bag House Filtration – Low pressure suction

The complete system design is based on low pressure suction enabling the system to consume very low power per ton of steel produced. The induced draft fan creates low pressure continuous suction capturing all fumes generated during melting, slagging, and tapping operations.

The dust-laden fumes are directed to a dry filtration Bag House where fine dust and metal oxides are removed.

The SPM levels at chimney outlet can reach below 30 mg/ Nm³ which are compliant to the most stringent norms in India.

The total system optimization reduces the power consumption to ~10 kWh/ton. The most important innovation to the Air pollution management for Induction furnaces is the development of Zinc extraction from the dust. The design of Bag House allows the dust recovery of ~ 0.5% of molten metal.

The collected dust, rich in Zinc Oxide, can be sold to recovery units at around ₹30 per kg, creating a new revenue stream which is sellable at ~₹30,000 per ton giving a revenue of Rs 150 per ton of Molten steel.

By combining environmental compliance with revenue generation, the Dog House system has become a sustainable solution. Our innovative solution helps capture ~ 95% fumes and reduce the cost of operating the pollution control Systems by making the dust collected sellable, which returns the capex within a year.

Dusting Removal with enclosed Conveyors

The value of the dust has forced us and the SMS plants to innovate on the handling & storage methods of the dust. In order to improve the collection percentage of the dust per ton of steel we developed and installed box-type dust conveyors.

These conveyors are designed for very fine dust. The design is for the fully enclosed outer structure to prevent dust escape. The overall spillage and material loss is minimized. The end result is clean shop floors and larger recovery of sellable dust.

Integrated Scrap Handling & Automation

The role of effective and efficient scrap feeding is critical for consistent melting rates and energy efficiency. If the Air pollution system is not compatible with the same, the operator will compromise on the pollution standards. This has been the story of Indian secondary sector for decades. We at Dev Energy design the Dog House system and engineered multiple automated feeding solutions for scrap handling to eliminate manual intervention and crane dependency while enhancing the operational excellence and productivity.

Scrap Feeding Trolley

The usage of specially designed Trolley which is suitable for both Scrap and DRI feeding makes the SMS feeding operations consistent, automated and eliminate the use of magnet with overhead cranes.

These trolleys are designed for hydraulic tilting force and remote-controlled operations. Their traverse speeds are ~30 m/ min. The trolleys are available in 3-ton and 5-ton one time feed capacity. The layout can be designed for trolleys to travel from front to back or back to front or side to side travel for flexible shop layouts.

The main point of design is to eliminate the need to remove the Dog House during scrap or DRI charging and the constant feeding of material into the furnace without extremes.

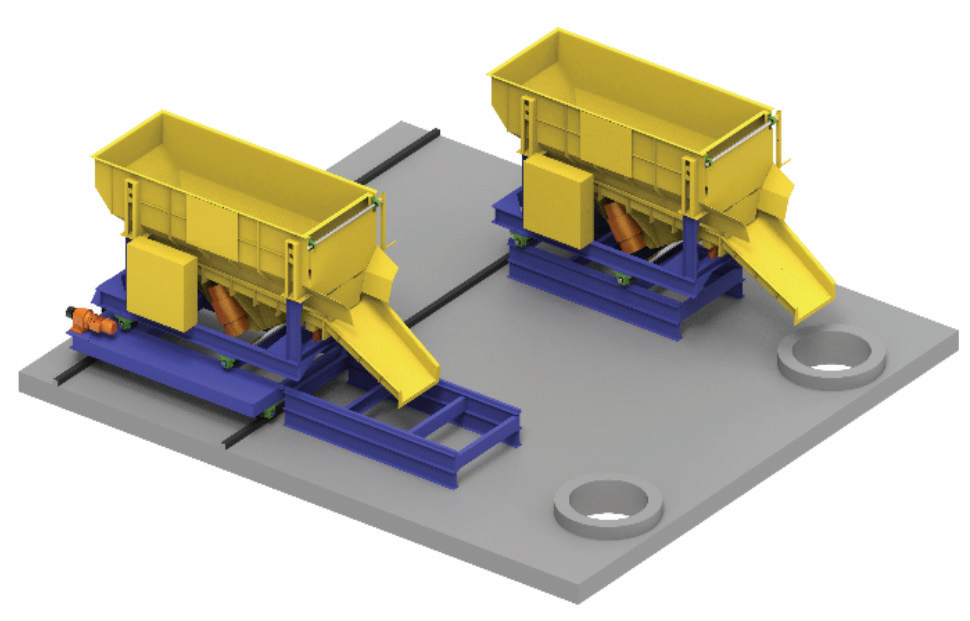

Vibro Charger

Similar to Trolleys, we have designed the vibro charger where the feeding is by vibrational movement of the floor. The constraint in selection of Vibro chargers is that the scrap should be completely shredded or sheared.

These chargers are able to transfers scrap into furnaces smoothly and safely into the furnace. They are better at providing the melting stability, reducing the safety risks and ensuring controlled feeding.

Scrap Pusher

The efficiency of Induction furnace is dependent on the meting rate and feed rate of the scrap and DRI. The only impediment in the maximization of same is the bridging at the mouth of the furnace. Scrap Pusher is innovative Hydraulic system with a telescopic boom to push the scrap into the furnace.

The system provides long stroke with small footprint. It offers benefits like increased reach in space constrained areas with high pushing force power. It is designed to complement the Dog House by operating within the required space and height while improving melting rates and more scrap per melting feeding cycle.

DRI Feeding System

The Induction furnace need constant feeding of Sponge Iron (DRI) and thus Dev Energy has developed a conveyor-based system. This system stores DRI in a hopper and transfers through covered conveyors, silos and vibro chutes. It enables safe, continuous and oxidation-free charging of DRI.

Ladle Transfer Car - Molten Metal Handling

Once molten metal is ready, it is safely transferred from the induction furnace to the caster using a ladle transfer car. The maximum fumes are generated in the transfer operation. Therefore. It is mandatory to have the Dog House operational and parked above the Induction furnace at the time of pouring of Molten metal

The ladle car is thus mandatory for operating furnace within the Dog House. This eliminated the operations by cranes where the ladles are transferred by overhead cranes. The final result is zero fume leakage during pouring and safe dust-free transfer of molten metal.

Conclusion

The success of modern steelmaking in efficient melting with sustainable operations. Dev Energy’s end-to-end solutions— from the scrap transfer and charging to fume extraction and dust recovery to molten metal transfer — integrated seamlessly to deliver higher productivity, lower operating costs, and assured environmental compliance.

Dev Energy has positioned itself as a trusted partner for SMS operators by combining practical knowledge, advanced engineering with automation to deliver cleaner, smarter and more profitable steel production.